Products

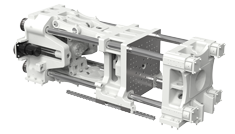

5-point toggle structure

The strength of the formwork is strengthened by professional mechanical analysis and design, and the elbow structure is stabilized by professional motion analysis and design.The central pressing effect of the V-shaped toggle mechanism makes the clamping force evenly transmitted to the mold.Reduce the clamping force and protect the life of the mold.

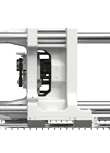

Thimble motor with brake

The thimble will not retreat even when the door is opened or the power is cut off, ensuring the safety of the operator

Linear guide rail is used for mobile template

Improve the load-bearing capacity of the mold; improve the parallelism and positioning accuracy of the template; reduce energy consumption; optimize the cleanliness of the mold area.

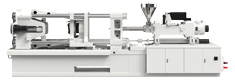

Full motor professional control

The control system is fully upgraded, equipped with a 15-inch touch screen, which enhances the human-computer interaction experience.

Top quality and durable

A full set of NSK transmission components, trade the best quality for the longest peace of mind.

Extremely accelerated response

Custom low-inertia servo motor, showing dynamic aesthetics under strong explosive force, acceleration response time is as short as 25ms.

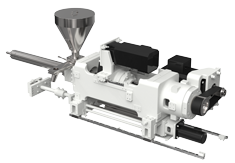

Body structure

Body positioning design, modular assembly, automatic welding.

Modular electric control cabinet design

The electrical control cabinet adopts EMC design to prevent interference, the system is safe and reliable, and the maintenance is convenient.

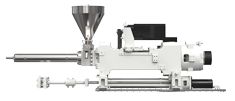

Double track structure

The injection starts quickly, runs smoothly, and has precise positioning.

Adjustable screw structure

The concentricity of the screw is guaranteed, and the production effect of optical-grade products can be easily realized.The hard alloy steel screw can improve the applicability of the screw and increase the life of the screw.

Language