Products

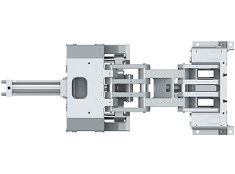

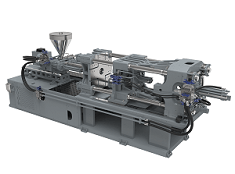

Reinforced toggle design

High rigidity joined toggle not only increases its concentricity but also improves the stability of platen movement.

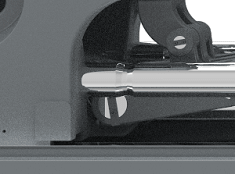

Lengthened stress groove

The lengthened stress groove effectively eliminates the stress concentration and prolongs service life of tie bar.

Box-type fixed platen

Well-distributed strengthened ribs guarantee better performance positioning of tie bar, minimum platen deflection, and even stress.

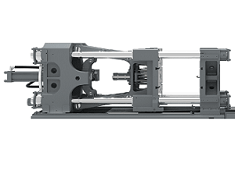

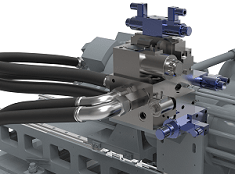

Balanced double cylinder structure

Balanced placed cylinders make nozzles positioning precisely, inject stably, and seal tightly as well as avoid leakage.

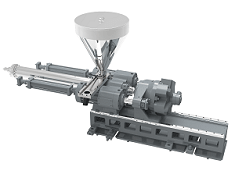

Proportional back pressure control

With proportional back pressure control, plasticizing becomes easily operated, and steadily ran.

Fast responding hydraulic controlling system

Fast responding nature makes it reaches maximum pressure (17.5Mpa) within 30ms. Improving productivity and shortening cycle time.

Stricter hydraulic safety standard

The entire series conforms to GB22530 and EN201 hydraulic safety standards.

Proportional back pressure control

Fast responding hydraulic controlling system

Stricter hydraulic safety standard

Rotary injection part

Rotary injection parts (equivalent ≥ i24000) can be equipped to optimize the cleaning speed and the difficulty of screw maintenance.

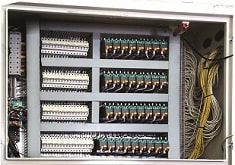

Professional electric layout with renowned components

Waterproof, dust resistant, sealed electric cabinets with world renowned components. Layout was optimized from aspects of high and low voltage separation, EMC, human operating habits, running feasibility and liability, precise control, and convenience of operating.

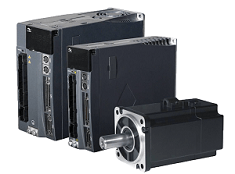

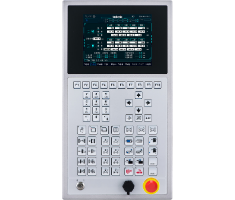

Specialized controller

Advanced controller with better performance of data transmitting and operation.

Language