This time at 2022 K, as a one-stop smart injection molding solution provider, Tederic links to advanced European molding process technology and will bring energy-efficient medical diagnostic class solutions. A NEO-E208c electric injection molding machine equipped with TLRE-06-900HQ automation integrated with efficient and precise production of 300UL pipette tips, one out of 48!

High Efficiency&Energy Saving Medical Diagnosis Solution

Machine:

NEO·E208c/e620h

product: Pipette Tips 300UL

Cavity: 48

Material: Medical PP

Weight: 0.32g

Cycle Time: 7-8s

Automation: Tederic TLRE-06-900HQ

Solution highlights:

- Configured to meet the ISO class 8 (10w) clean room environmental production standard.

- High resolution control system is perfect for high-precision multi-cavity molds, with a product weight accuracy of 0.1%.

- With high repeat accuracy of 0,1%, ensure the product dimensions meet the European market's requirements.

Wide range of applications in the medical industry

In the medical industry, especially since the New Crown epidemic, Tederic has worked with medical companies such as Yangpu Medical, Lian Yu Precision, and Paxton Technology with the advantages of cleanliness, high efficiency, and energy saving, and can customize "replicable, scalable and universal" solutions according to the needs of the companies, while ensuring a cost-effective return on investment.

We have a wide range of experience in medical product solutions such as medical centrifuge cups, 1ml/2ml pushers, blood collection tubes, test kits, infusion bottle caps, deep well plates, indwelling needle tees, and more.

Hundreds of Tederic Electric injection molding machines at customer sites

Tederic NEO·E electric injection molding machine

Clean, efficient, durable, and energy efficient

The medical industry has strict regulatory requirements for the production environment, equipment design, and production process and special requirements for the use and routine maintenance of production equipment. The cleanliness of the products is high, the audit is strict, and the inspection pass rate needs to be above 99%. In terms of equipment, the medical industry has high investment costs and requires efficient and stable production in large quantities.

Tederic NEO·E series electric injection molding machine injection speed up to 500 mm / second, injection position repeatability up to 0.01 mm, with high injection accuracy, fast injection speed, clean and easy maintenance, and other advantages suitable for medical industry applications.

Machine highlights

With a special lacquered surface that is easy to clean for mold removal, the mold area is wrapped in stainless steel and equipped with a contactless tie bar, fully compliant with ISO Class 8 (Class 10W) clean room design standards in manufacturing production.

- High efficiency and precision

Empty cycle times are reduced by 16-31%, and overall plasticizing capacity is increased by 25%, with a further 30% increase in plasticizing capacity for the pp-specific screw. In addition, the movement is better articulated, allowing for compound movements. Servo 24-bit encoder control with ±0.01mm opening and closing accuracy.

The state-of-the-art energy recovery system allows the braking energy of the injection molding machine movements to be recycled. In addition, energy is no longer consumed in the form of heat, resulting in reduced heat exchange requirements in the clean room and a further energy saving of 8%-15% compared to conventional motors.

The reinforced formwork design provides 45%-55% of the deformation of conventional formwork; secondly, the specially formulated formwork has a hardness of 190 HB or more, guaranteeing the life of the multi-cavity precision mold and ensuring no indentation for a long time. It also has a screw monitoring function and a power failure self-protection function.

Presently, Tederic's

NEO·E series electric injection molding machines have covered a series of models ranging from 55 to 1088 tonnes, which have gained wide recognition from customers, especially in the fields of medical, automotive, packaging, and other large precision plastic product molding.

In 2021, the first 1088-tonne large electric injection molding machine developed by Tederic was purchased by a well-known French company. Today, hundreds of motors are exported to many countries and regions, such as France and the USA. With the continuous development and launch of large electric injection molding machines such as the 1408 tonne, Tederic's future market competitiveness will be continuously enhanced.

For the demonstration of

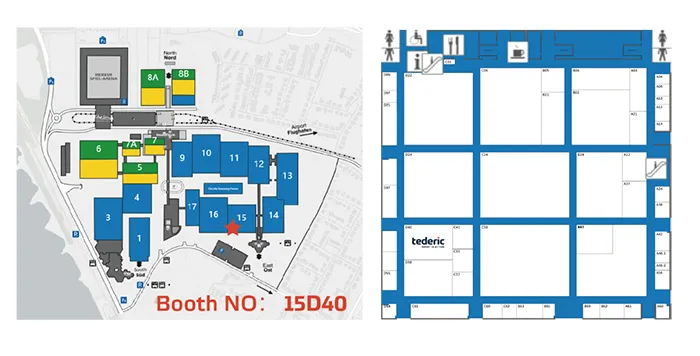

NEO·E's medical solution at the K show, Tederic is very confident that it will attract the attention of customers worldwide. Customers are welcome to visit us at booth 15D40 at the K Show in Germany or visit www.tedericglobal.com!