As a leading injection molding machine manufacturer and smart injection molding solution provider, Tederic closely follows the changes in the industry and takes the path of deep integration of intelligence and green energy to expand new business application possibilities and provide more efficient and reliable solutions for global customers.

At the upcoming K-Show, Tederic will present a surprisingly low energy consumption and sustainable application solution - a 100% biodegradable tableware solution, showcasing Tederic's innovative material applications, new generation servo systems, and other technical strengths and social responsibilities for global customers to help the sustainable development of the circular economy, with the following product highlights.

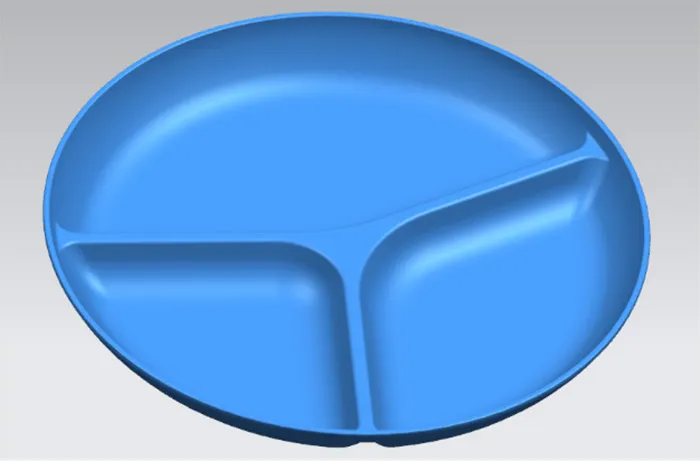

Packaging - 100% biodegradable Cutlery

Solution:

Machine:

NEO·T160

product: 100% Biodegradable Cutlery

Cavity: 1

Material: PLA

Weight: 158g

Cycle Time: 68s

Automation: Tederic TLRE-06-800

Solution Highlights

- Solves the problem of poor heat resistance of PLA materials. Parts have a high-temperature threshold of 100⁰C

- Material can be fully biodegradable and meets all food contact requirements in GB/T, EN, ASTM, and FDA standards.

Machine Highlights:

- Stable & Durable: an optimized toggle movement curve and a double linear bearing injection unit design make the machine more stable, reliable, and durable.

- High Efficiency: servo system ultra-fast response, with idle to peak pressure in 28ms, shortens cycle times and reduces power consumption.

- Energy Saving: a new generation of servo power systems reduces power consumption by 30% to 80% when compared to traditional hydraulic presses.

- Precision: Mold open and close position repeatability is ±0.01mm, and product weight maintained within 0.3%.

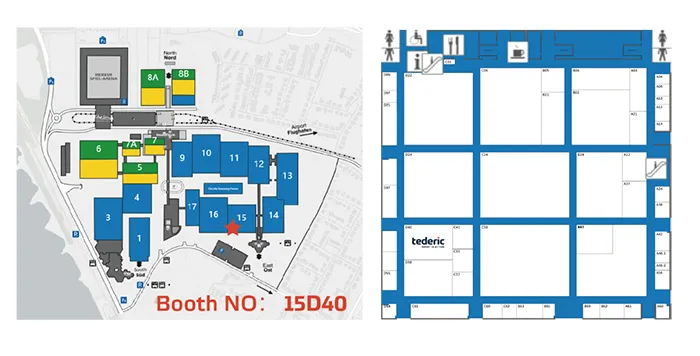

During the exhibition, to help our partners and new and existing customers to further understand the characteristics of Tederic's products, our professional staff will be on hand to conduct application demonstrations of sustainable solutions. Chinese customers attending the K-Show in Germany are welcome to visit us at our booth (Hall 15, D40).