At the site of the ceremony, Yu Huiyou, Secretary of the CPC Tongxiang Municipal Committee, announced the official opening of the integrated molding high-end equipment project of Tederic Equipment Co. Tu Jianzhong, Party Secretary of Tongxiang Economic Development Zone, Wang Jian, Mayor of Tongxiang Municipal People's Government, and He Ying, Vice President of Tederic Machinery Co.

01.

Open integrated molding high-end equipment project with the trend

In recent years, the new energy automobile industry has been booming in the energy saving and emission reduction double carbon policy and the global energy crisis background. The "aluminum instead of steel" and "generation more" one-piece die-casting molding process because of its lightweight, environmental protection, cost, and other aspects advantages so that the industry into the "big die-casting era." The die-casting market, especially the automotive industry, will predictably increase the demand for heavy-duty die-casting machines. Tederic has nearly 20 years of experience in the injection molding industry. With the advantages of "industry-related," "market-related," and "customer-related," we are entering the high-end equipment of integrated molding. The construction of the integrated molding plant has started.

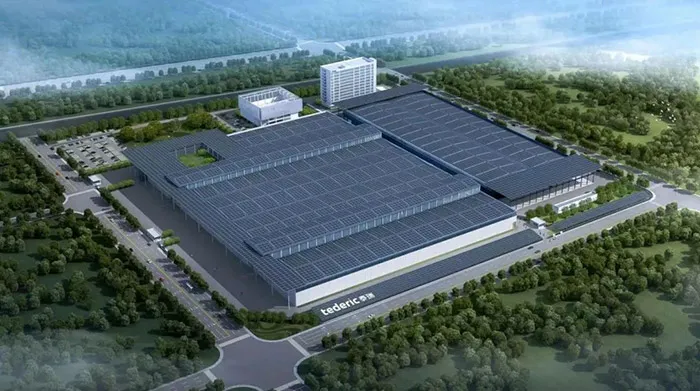

The construction of a high-end integrated molding equipment construction project is located in the Tongxiang Economic Development Zone, east of Wenhe Road, south of Gaoxin Road 3, west of Nanri Port, and north of Gaoxin Road 4, covering an area of 247 mu, and will be officially put into use in 2023.

The base will be developed into an industrial base for highly efficient and intelligent integrated molding equipment. The production workshop is equipped with flexible production lines, high-precision machining equipment groups, several 300-ton floor boring machines and gantries, several 300-ton cranes, heat treatment lines, and other supporting equipment for the entire industrial chain. It can meet the manufacturing of a whole series of die-casting machines below 15,000 tons, providing customers with better products, faster delivery, and a full range of services such as mold trial and training. Completing this base is a symbol and milestone of Tederic's entry into the field of high-end equipment for integrated molding.

02.

The "0" carbon factory of the future

The construction of the integrated molding high-end equipment project also signifies Tederic's green social responsibility as a practitioner of Made in China 2025 and the "30.60" target.

It is reported that the selection of equipment for the production and auxiliary production units of the base is based on the rational use of energy-efficient equipment. The rooftop uses 8MW of photovoltaic power generation, and 80% of energy consumption uses green power solar energy, making it a veritable "0-carbon" factory of the future. With the new model of the factory of the future, the factory will also aim to build an intelligent benchmark, focusing on digital design, intelligent production, networked collaboration, shared manufacturing, personalized customization, service extension, and other application scenarios to achieve digital management and control of the entire business flow of research and development, design, manufacturing, and operation management to ensure high-quality and rapid delivery for customers.

The start of the integrated molding high-end equipment construction project means that Tederic is market-oriented and has officially entered the integrated high-end equipment industry! After completing the project, it will become a new benchmark in the global molding industry. Tederic will have the strength to provide comprehensive molding solutions for customers in the new energy vehicle industry, such as plastic molding and metal molding, and also provide strong support for Tongxiang to build a 100 billion industry cluster of high-end equipment for new energy vehicles.