01.

Injection Molding Compression Application

Riding on the back of the dual carbon policy, new energy vehicles for low-carbon mobility have become a big hit in the market. They have brought new growth opportunities for injection molding machines. To give visitors to the K Show an insight into Tederic's pioneering technology and capabilities, we worked with our partners to deliver a demonstration program to showcase Tederic's expertise in this area and the advantages and quality improvements that can be achieved using a combination of processes.

Solution:

Machine:

NEO·M1120s/e1700c e1100c

product: High Gloss B Pillar

Cavity: 2

Material: ABS+PMMA

Weight: 220g(ABS 100g+PMMA120g)

Cycle Time: 85s

Automation: Tederic Integrated Automation Solution

Solution Highlights

- Molding at reduced pressure improves optical performance and meets the stringent requirements for optical components, reducing energy losses and manufacturing costs.

- The position and force of each tie bar are independently controlled. During injection-compression molding (Coinsure™), tie bar positional accuracy is as high as ±0.01mm static, ensuring perfect dimensional accuracy of the product.

- Lighter than glass, with a 40% weight reduction, product design can be more complex than is possible in glass; much tougher than glass.

- The optical component is integrated during molding, reducing the required investment.

02.

Tederic's multi-component injection molding machine helps low carbon manufacturing of new energy vehicles.

As one of Tederic's core competencies, the

NEO·M1120s horizontal electric injection molding machine has excellent performance. Its turntable with braked servo drive and ample swing space can adapt to many customers' process needs. The self-contained electric injection components not only improve the molding accuracy but also further enhance the molding efficiency with a high return on capital.

▲

NEO·M was awarded "Outstanding Product of Machinery Industry in the 40th Anniversary of Reform and Opening-up".

First Prize of Zhejiang Province Science and Technology Progress Award two times, etc.

03.

What makes CoinSure™ "great."

The Tederic CoinSure™ injection compression molding process involves the injection molding machine building two clamping pressures into the mold closing process, one at low pressure and the other at the usual high pressure. The injection is completed instantaneously during the ramp-up, solving the problem of sudden pressure changes caused by conventional mold closing methods.

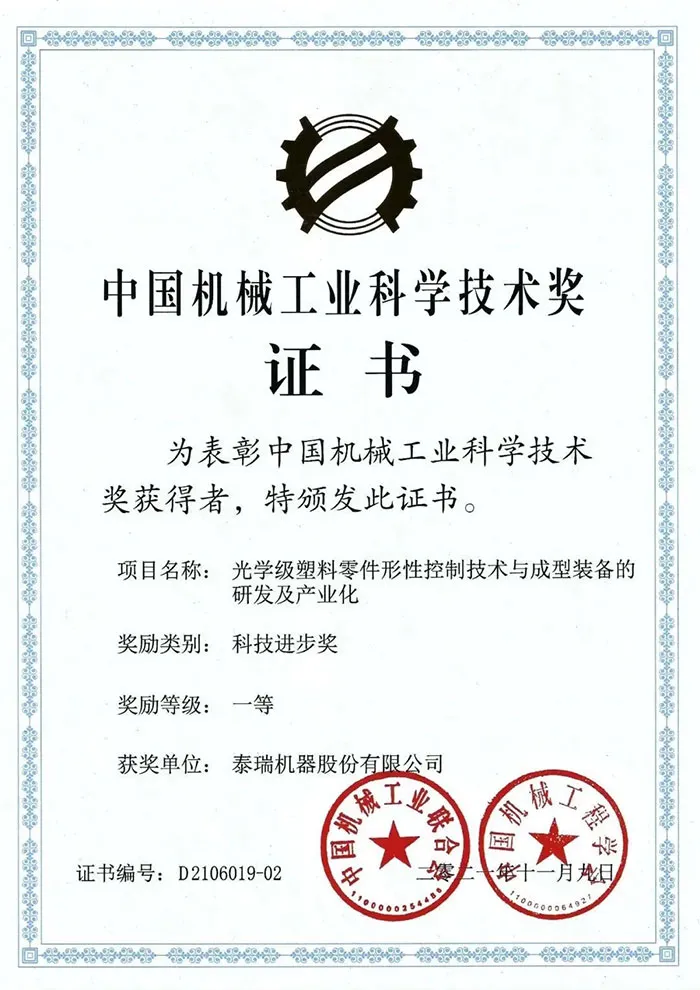

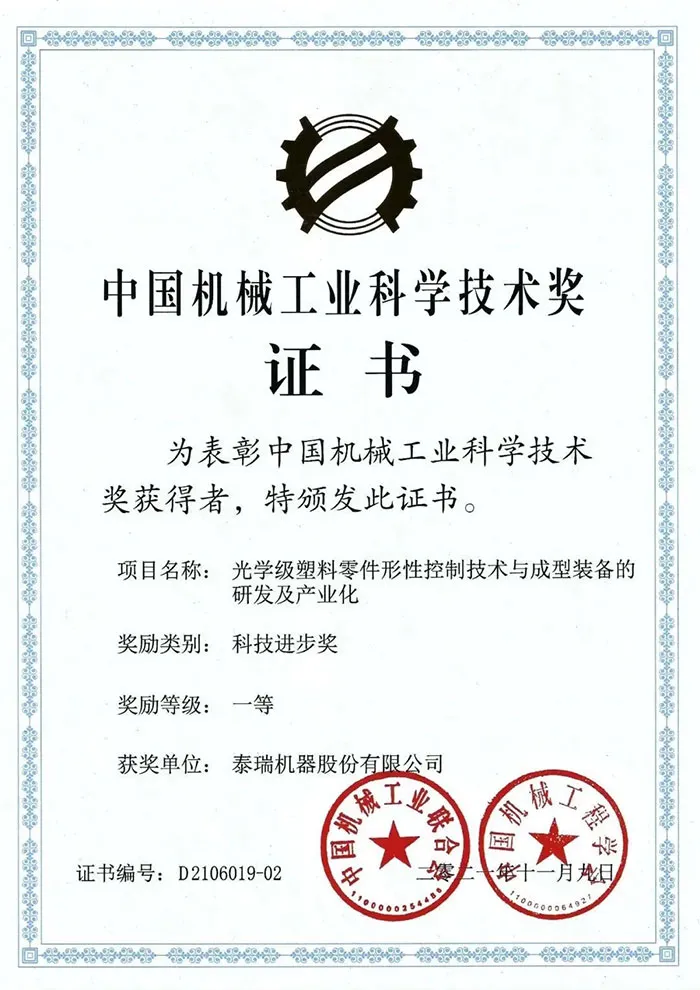

This technology has achieved three major technological innovations, namely horizontal heavy-duty turntable opposed molding and dynamic balancing technology of the mold plate, multi-directional collaborative multi-layer integral injection and secondary mold closing process and high-precision double-loop control method of the injection molding system, which won not only the First Prize of Science and Technology Progress Award of the 2021 China Machinery Industry Science and Technology Award but also the main indexes were tested by the industry's authoritative testing institutions. The aberration of the optical products produced was only 1/8. 8, also on behalf of the Chinese brand, completely broke the long-term monopoly situation of foreign countries.

The process not only enhances the optical performance of the product and meets the quality requirements of the optical parts of the product. The integrated molding ensures perfect dimensional accuracy of the product while reducing mold losses and energy consumption of the injection molding machine, reducing customer costs. It is suitable for molding products that require high precision and quality, such as transparent parts for automobiles, headlights, lenses, and high-precision optical parts for defense, aerospace, and deep-sea exploration.

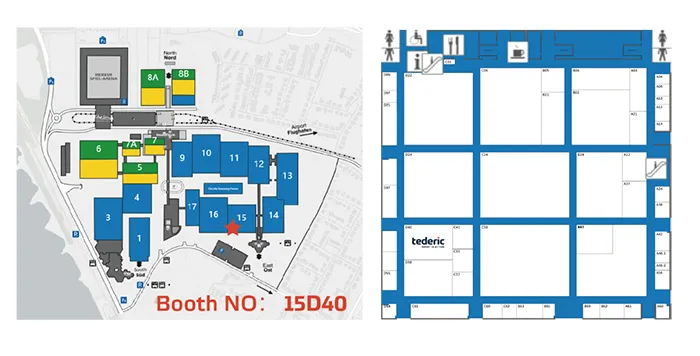

We welcome you to visit us at booth 15D40 at K in Germany or browse to learn more!