The event's theme is "Circular Economy, Climate Protection and Digitalisation."

In 2022K, we will showcase our innovative product line -- NEO series and bring 3 turnkey solutions: An injection compression molding process, high efficiency&energy saving medical diagnosis solution, and 100% biodegradable cutlery.

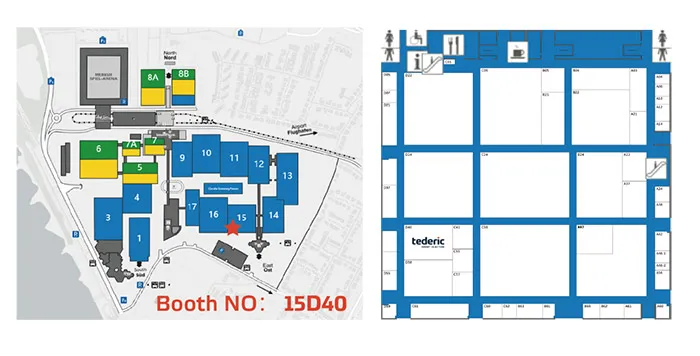

01. Tederic active on the world stage

4 overseas subsidiaries, an R&D center in Germany, 65 sales outlets, 36 equipment depots, and service centers, and hundreds+ after-sales service teams.

Today, Tederic's overseas business has involved more than 130 countries and regions in North America, South America, Europe, Africa, Oceania, and Asia, with applications in the automotive, home appliance, medical, packaging, and logistics industries, making it one of the world's best-known Chinese injection molding machine brands.

02. Deepening the European Highland Market

Tederic is increasing investment in R&D and marketing in the global high ground of Europe.

We have now successfully entered the European market. Hundreds of NEO motors are sold in France. Become the largest injection molding machine brand in the Portuguese injection molding machine market.

▲Photograph of Germany and Portugal open house

03. Tederic's three innovative solutions present a surprise

The global energy crisis is intensifying. The demand for innovative material applications and energy-efficient injection molding equipment is growing.

The NEO series presents three intelligent injection molding solutions as below.

01. Injection Compression Molding Process

Machine:

NEO·M1120s/e1700c e1100c

product: High Gloss B Pillar

Solution Highlights:

- Molding at reduced pressure reduces the internal stresses within optical parts, improves optical performance, meets the other stringent requirements for optical components, and reduces energy losses of the mold and machine, lowering manufacturing costs.

- The position and force of each tie bar are independently controlled. During injection compression molding (Coinsure™), tie bar positional accuracy is as high as ±0.01mm static, ensuring perfect dimensional accuracy of the product.

- The advantages of products produced by this process are: lighter than glass, with a 40% weight reduction; product design, particularly for curved surfaces, can be more complex than is possible in glass; much tougher than glass.

- The optical component is integrated during molding, reducing the required investment.

02. High Efficiency&Energy Saving Medical Diagnosis Solution

Machine:

NEO·E208c/e620h

product: Pipette Tips 300UL

Solution Highlights:

- Configured to meet the ISO class 8 (10w) clean room environmental production standard.

- Advanced energy recovery system reduces energy consumption by 10% when compared to other injection molding machine brands.

03.100% Biodegradable Cutlery

Machine:

NEO·T160

product: 100% Biodegradable Cutlery

Solution Highlights:

- Solves the problem of poor heat resistance of PLA materials. Parts have a high-temperature threshold of 100⁰C.

- Material can be fully biodegradable and meets all food contact requirements in GB/T, EN, ASTM, and FDA standards.

Live demonstration of the joint umati demonstrator. Real-time data from Tederic Smart Injection Molding - MES system. Visit us to find out more about our solutions.