11/30/2020

Last week, tederic appeared at the 15th China Pallet International Conference, a grand event for the pallet industry, to discuss the development of China’s pallet industry together with other guests from the industry. At the Conference, tederic shared the ultra-efficient and lightweight injection molding pallet solution with the participants, and the ultra-light pallet with tederic CellSure™ micro-foaming technology was eye-catching.

As a unitized logistics appliance for efficient logistics, the pallet runs through the connection points of all links in the modern logistics system. It plays a role in the horizontal sharing of resources.

During World War II, pallets were first used in cargo transport by the US military. Since then, pallets have become one of the innovations in the logistics industry and laid a foundation for the development of sharing economy. The pallet standard plays a role in market protection for importing and exporting commodities as a technical barrier to trade in the international market.

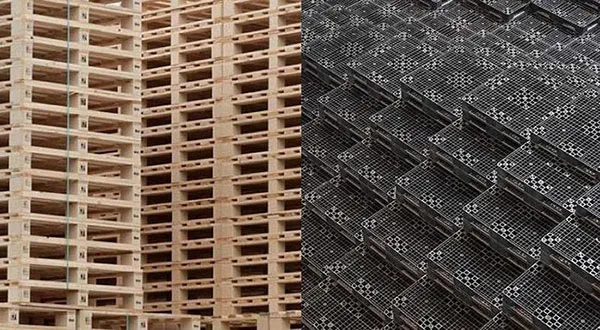

According to the 2020 China Pallet Market Application Survey Data Report, the use of wooden pallets dropped to 74% from 80% of the full pallets in 2012, while plastic pallets increased to 16% from 12% in 2012, and the ratio of disposable to recycling pallets was about 1:8. The development of the logistics supply chain requires higher distribution efficiency, storage efficiency, and transport efficiency. As the smallest unit in the logistics chain, plastic pallets instead of wooden pallets is an inevitable development trend. The pallet should be easier to handle and better recycled in the actual application. At the same time, the complicated stacking requires higher compression resistance for pallets.

01. Modern logistics work puts forward three critical requirements for pallets:

lighter, more durable, and more compression-resistant

Compared with wooden pallets, ordinary plastic pallets are lighter. But how to further reduce the weight of regular plastic pallets to make them more durable and compression-resistant? Micro-foaming technology provides an effective solution.

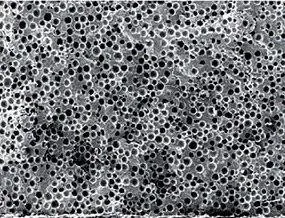

Plastic products made with micro-foaming technology are present due to the internal microporous structure of the external solid layer. Compared with standard technology, the microporous form similar to the honeycomb structure can reduce the weight of products of the same quality by 12%-20% while increasing the mechanical strength by more than twice. In actual production, lower clamping force requirements can reduce energy consumption and molding cycle in the production process, improve productivity and efficiency. Damaged pallets can also be recycled for reuse.

02. How does tederic’s CellSure™ micro-foaming technology work?

After nitrogen and plastic are mixed into the mold using tederic CellSure™ micro-foaming technology, the bubbles nucleate and grow with a sudden pressure drop. The molded product has a smooth surface and a uniform porous structure inside, which can reduce the product weight, shorten the molding cycle, eliminate shrinkage marks, and ensure the stable size of finished products.

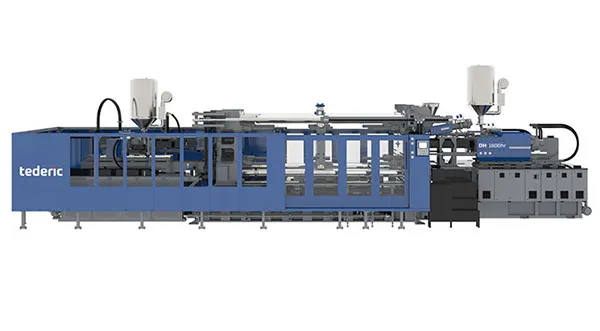

03. Pallet Solution with tederic CellSure™ Micro-foaming Technology

The application of tederic CellSure™ micro-foaming technology on the opposite-injection machine provides more possibilities: doubled output, space-saving, and two-color pallets can be produced.

Language