2021.06.3

Material type: PMMA+ABS

Number of cavities: 2

Molding cycle: 90S

Product unit weight: 478g

The application and trend of mature horizontal turntables in the automotive industry

High-light parts solution demonstration

Equipped with the electric injection unit and ensuring the repeat accuracy of product weight, it also realizes stable high-pressure and low-speed filling characteristics to ensure the stability of mold filling.

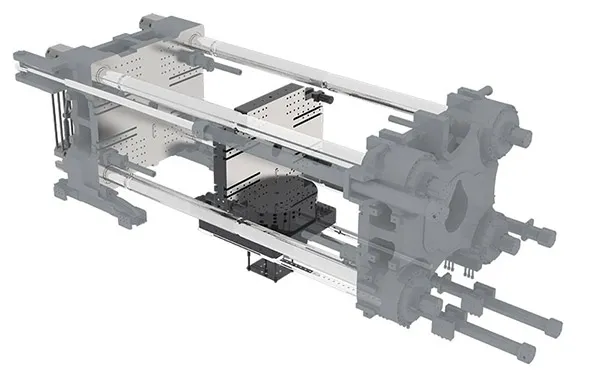

The SpinSure®-H horizontal rotary table technology combines the middle-platen horizontal rotation function and the modular injection unit between frameworks of clamping units of two-platen injection molding machines, thus providing sufficient rotation space for the rotary table and allowing the mold to rotate beyond the space between tie bars.

High load-bearing capacity: The horizontal rotary table support structure can bear up to 50 tons of mold weight;

Suitable for large molds: It allows the mold to rotate beyond the space between tie bars, breaking through the limitation of traditional injection molding machines to molds;

Personalized customization: It can be customized according to actual production needs.

The high-end industry has higher quality standards for the surface effect of plastic products. The high-quality production requirements of plastic products on the injection molding machine can be easily achieved using GlosSure™ high-gloss processing technology. After the double-layer product is formed, it visually achieves the high-gloss effect on the surface of plastic products while improving the surface hardness.

High-quality: The plastic product has a high surface finish and beautiful visual effect;

Efficient: The product molding is realized at one time, without subsequent processing procedures such as laminating, coating, painting;

Stable: Special high-gloss plasticizing screws and components are used to improve the qualitative effect of sizing materials.

NEO•M has industry-leading multi-color injection molding technology, flexible modularization, professional customized design to meet your diverse process needs. Tederic continues to innovate and explore the possibilities of injection molding.

Precision: The injection units adopt a single-cylinder, one-line injection structure, Injection repeat accuracy of less than 0.2%

Stable: Rotary table is driven by servo motor; Horizontal rotary table for moving platen rotates smoothly and stably; Give full play to the advantages of its complete industrial chain to ensure the quality and accuracy of the rotary table

Efficient: Simplified product procedures make it form at one shot successfully from multi-steps.

Versatile: Modular design of injection unit can be freely arranged, with up to 30+ combinations, it can be equipped with up to 6 injection units for simultaneous operation. The maximum diameter of the turntable is 2250 mm.

Energy-saving: New generation of servo system

Language