2021 April 19

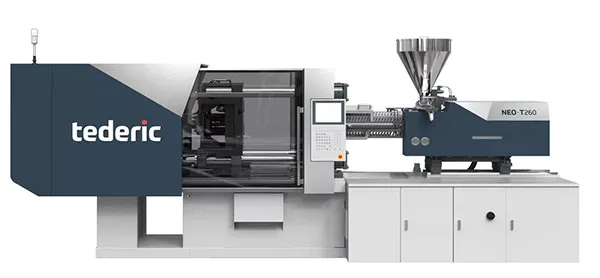

Ningbo Zhenfei Decorated Curtain CO.Ltd., located in Yuyao, Ningbo, is now the largest manufacturer of smart curtains and parts in China. The annual output of window decoration plastic parts is as high as 840 million pieces, the number of curtains is 4 million pairs, and the total output value is about 350 million RMB. At the same time, based on a high level of trust in the Tederic brand and products, Ningbo Zhenfei Decorated Curtain CO.Ltd. is also the first customer of Tederic's new high-end injection molding machine NEO series. In this issue of "NEO's famous factory," we have a glimpse of the advantages and highlights of the Tederic brand and NEO series models from Ningbo Zhenfei Decorated Curtain CO.Ltd. 's General Manager Lu Jiefei.

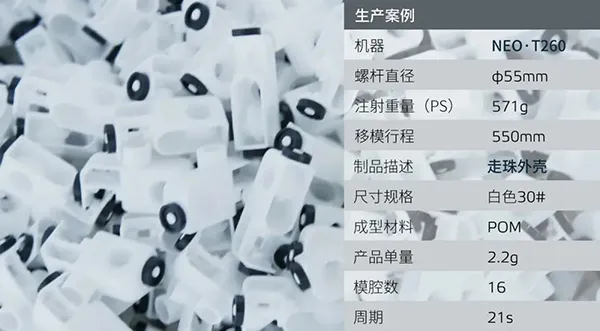

"The injection cycle of NEO·T260 is only 21 seconds, 1-2 seconds faster than the same type of machine, and the efficiency is increased by about 9%. This is a strong competitive advantage for Zhenfei's products. In terms of energy consumption, NEO· T260's actual production energy consumption test data is 0.3335KW⋅h/kg, which saves energy by 13.4%." said Lu Jiefei.

|

Energy consumption monitoring report

|

||

|

Sample name

|

The NEO series of Tederic Machinery

|

A well-known brand injection molding machine

|

|

Machine specifications

|

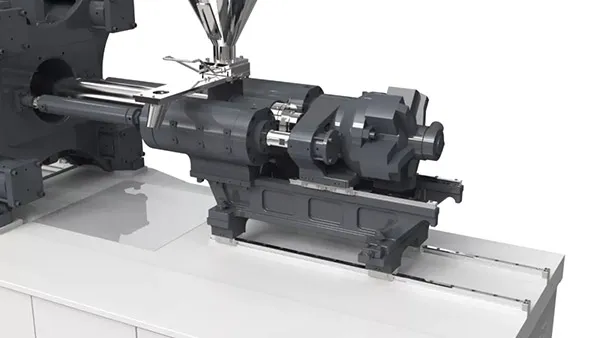

NEO.T260Toggle Clamp Injection Molding Machine Clamping force:2600kN

Screw diameter:Φ55 |

Toggle Clamp Injection Molding Machine Clamping force:2500kN

Screw diameter:Φ50 |

|

Monitoring basis

|

GB/T 25156.2020 (General technical requirements inspection methods for rubber plastic injection molding machines)

GB/T30200.2013(Energy consumption detection method for rubber plastic injection molding machine)

|

|

|

Test results |

Actual production energy consumption: Tederic saves energy by 13.4% |

|

|

0.3335kw·h/kg

|

0.3852kw·h/kg

|

|

|

Dural parallelism

|

||

|

0.09mm

|

0.20mm

|

|

|

Injection weight repeatability

|

||

|

0.295%

|

0.816%

|

|

Generally speaking, plastic products in the window decoration industry have minor effects and mold cavities. Many parts need to be assembled automatically after injection molding. Therefore, it poses a significant challenge for product accuracy and injection molding accuracy of injection molding machines. In this regard, Lu Jiefei said that the reason for choosing Tederic's NEO·T260 injection molding machine is to trust Tederic's brand on the one hand and to be optimistic about its outstanding performance in terms of stability, injection accuracy, injection efficiency, and energy consumption on the other.

| Production case | |

|

Machine |

NEO•T260 |

|

Screw diameter |

Φ55mm |

|

Injection weight(PS) |

571g |

|

Clamping force |

550mm |

|

Product Description |

|

|

Dimensions |

white30# |

|

Molding materials |

POM |

|

The weight of a product |

2.2g |

|

膜腔数 |

16 |

|

Cycle |

21s |

"On the day the machine entered the factory, Tederic sent a professional sales service factory engineer to accompany us throughout the entire process to provide us with timely and rapid professional installation and commissioning and on-site technical operation training guidance. Over the past few months, We have received targeted customer return visits and care from Tederic's technical and application engineering departments many times. and felt the professionalism and rigor of their entire service system process."

At present, Tederic's after-sales service team has hundreds of service engineers, 70% of whom have more than decades of experience in the field of injection molding machines. At the same time, Tederic will provide customers with global 24h no time difference services; it has excellent advantages in professionalism and response speed.

In 2020, Tederic initiated a brand remodeling project, taking "smart injection molding" as an important strategic point for the company to face the future and develop and innovate. This coincides with Tederic's "smart injection" brand positioning. It means that Tederic will always focus on the obsession and spirit of injection molding machines and deliver flexibility. Tederic people who respond and have open minds bring customers more energy-saving, environmentally friendly, efficient, and intelligent injection molding machine solutions.

Tederic's new headquarters building and the all-electric injection molding machine smart factory 4.0 are expected to be completed and put into production in 2022. The project has invested more than 1 billion yuan shortly, covers an area of approximately 33,334 square meters, and has a total construction area of approximately 75,119.44 square meters. It is about taking more significant steps in "intelligent injection molding."

"Tederic's team is full of passion and pioneering spirit. I believe that they can overtake in terms of data and intelligence. I look forward to creating a new world with Tederic and other partners!" Lu Jiefei said.

Language