Mr. Zhang Hongpeng, general manager of the Tederic Die-casting Machine Division, Mr. Dan Zhaoxue, chairman of Hongtu, Mr. Lu Rencong, chairman of Nanfeng, Mr. Zhang Qinyong, chairman of Huafeng, and Mrs. Zhang Ying, chairman of Runxingtai, attended the signing ceremony.

IKON die casting machine launch ceremony

01Strategic cooperation to jointly develop the integration of automotive parts die-casting circuit

Tederic & Hongtu Technology

The two sides signed a strategic cooperation agreement

Guangdong Hongtu Technology(Holdings) Co., Ltd.

Guangdong Hongtu Technology Co., LTD., founded in 2000, is a global leading manufacturer of high-end auto parts die casting. Focus on automotive aluminum alloy molding, plastic surface treatment, material research and development, and intelligent integrated technology products R & D, development and manufacturing. In recent years, Hongtu actively explored the new energy vehicle market accelerated the transformation and upgrading of products, and successfully developed several new customers such as GAC Aean, Ningde Times, NiO Auto structural parts, and chassis safety parts products. In June 2022, Hongtu reached cooperation with XPeng Motors and became the supplier of integrated structural parts for a certain model of XPeng Motors.

Tederic & Nan Feng auto Parts

The two sides signed a strategic cooperation agreement

Taicang Nanfeng Auto Parts Co., LTD

Taicang Nanfeng Auto Accessories Co., Ltd. is located in the Economic Development Zone of Taicang City, Jiangsu Province. It is one of the production bases of the head of the domestic cylinder body, cylinder cover, and steering shaft. Nanfeng Auto Parts is committed to providing manufacturing services for the automotive industry and auto parts enterprises. It is a professional processing enterprise mainly producing aluminum alloy cylinder bodies, cylinder covers, compressor assemblies, automobile steering shafts, engine support, and other auto parts and is an excellent supplier of SAIC.

Tederic & Huafeng Power

The two sides signed a strategic cooperation agreement

Yingkou Huafeng Power Development Co., LTD

Yingkou Huafeng Power Development Co., LTD., founded in 2008, is a high-tech enterprise focusing on the research and development, production, and sales of aluminum alloy auto parts and the largest manufacturer of high-silicon aluminum alloy auto parts in Northeast China. The company's leading products are various aluminum alloy auto parts and automobile engine cylinder blocks, etc., and its achievements are prominent in the field of engine cylinder block production.

Tederic & Run Xingtai

The two sides signed a strategic cooperation agreement

Zhuhai Runxingtai Electric Co., LTD

Zhuhai Runxingtai Electric Co., Ltd. was established in June 2002, committed to high-end light alloy die-casting structural parts design, research and development, production and sales of precision intelligent manufacturing excellence enterprises, its master of the core technology semi-solid rheological forming technology overall process technology has reached the international leading level. Widely used in the new generation of 5G communications, new energy vehicles, photovoltaic, energy storage, industrial robots, rail transit, aerospace, and other fields.

02Combination of strong forces

Tederic die-casting technology helps users "improve quality and efficiency"

With the "die casting technology" frequently included in the national industrial development plan, automotive aluminum alloy and integrated die-casting technology have produced "subversive innovation" for traditional automobiles.

Including body, chassis, and other large structural parts integrated, integrated die casting, the original riveting, stamping, welding, and forging of the complex process to simplify. Reducing the processing technology, reducing the weight of parts, and achieving cost reduction has become the inevitable trend of the development of the industry at this stage.

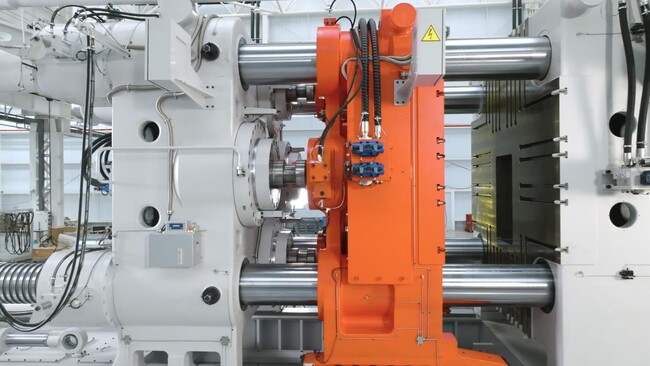

▲IKON three plates direct pressure type large die-casting machine

As an enterprise deeply engaged in molding equipment, Tederic is well-versed in the reliability technology of large-scale molding equipment. Given the requirements of ultra-large structural parts and customer pain points, in-depth research has been carried out in the design and development of ultra-large structural parts, heat-treat-free materials, ultra-large mold design and process development, ultra-large die casting machine design, manufacturing, and the overall integration of intelligent ultra-large integrated die casting units.

Previously, the team members of the Tederic Die Casting Machine Division integrated European die-casting machine technology, talent, and resources to devote themselves to research and development. With the successful development of a full range of die-casting machine products ranging from 1400 tons to 9200 tons, Tederic die-casting technology will meet the development and application of automotive precision parts die-casting with larger sizes and more integrated components.

▲IKON three plates direct pressure type large die-casting machine

Given the user's pain point problem, in the injection process, Tederic independently developed a fully closed-loop SNP real-time control injection system. The system integrates MCK large model self-learning algorithm to realize intelligent monitoring, analysis, and adjustment of the machine, significantly improving the real-time control accuracy, making the injection process have the advantages of smooth start, timely speed response, high accuracy, saving pressurization time, etc., to help users provide production efficiency.

In terms of the mold closing process, Tederic independently developed the industry's first three-plate direct pressure structure, achieving speed repetition accuracy of ±1%, pressure repetition accuracy of ±1bar, and position repetition accuracy of ±2mm. The process has four main advantages:

- The mode-locking force is distributed more evenly. Reduce waste generation and improve die-casting accuracy;

- Adaptive adjustment of clamping force. Improve die-casting accuracy and extend machine life;

- The use elongation of the plate material in the mold closing is high, and it has weldability. No need to replace the middle plate, reduce customer production costs;

- The hinge structure is replaced by four high-pressure cylinders. Fundamentally solve mold adjustment difficulties and hinge wear resulting in reduced accuracy, reduced downtime and maintenance time, and maintenance costs.

Work together for a win-win future. With the successful signing of the strategic cooperation agreement, Tederic and several well-known industry enterprises in the field of ultra-large integrated structural parts molding equipment joint research and development officially opened.

We expect that shortly, the two parties will continue to promote the in-depth development of cooperation and form a strong synergy in the field of die casting. Bring technological breakthroughs in the field of automotive precision parts die casting, and provide strong momentum for platform building, resource sharing, and brand development under new trends and new formats!