11/9/2020

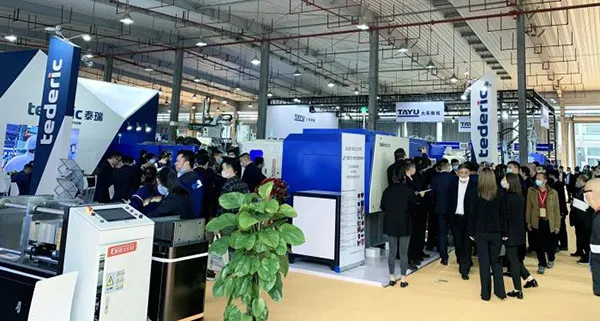

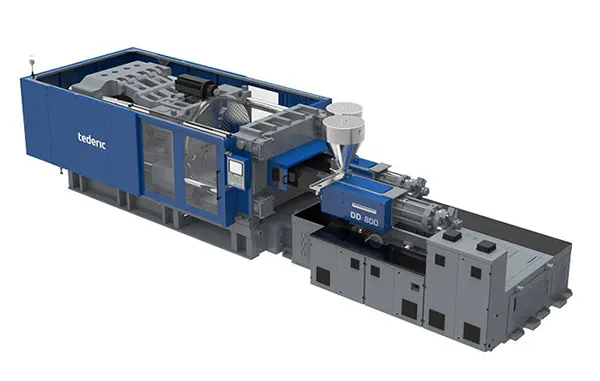

Tederic appeared at the China International Plastics Expo 2020 with two Dream series products of DD.800mm precision two-color injection molding machine for laptops and DE.325f electric high-speed machine for thin-walled packaging, bringing efficient and complete injection molding solutions and technical experience to customers and visitors.

High-quality plastic packaging products require unique labels and high-quality graphics. tederic LabelSure™ in-mold labeling molding technology improves product quality and production efficiency while reducing material wastage. This technology has been equipped for tederic Dream T and H series.

It is a process to put the pre-made label paper into the mold cavity of the injection molding machine for product production. After injection molding, the label paper of PP material can be closely integrated with the product. Due to the particularity of its material, the product can be better protected and decorated. In the high-speed molding solution of the IML coffee cup at the exhibition, a single mug weights 6g, with a molding time of 4s, and 8 cups can be molded each time.

Benefits of LabelSure™ In-mold Labeling Technology

Applications of LabelSure™ In-mold Labeling Molding Technology

It is an independent rotary table control unit of tederic, and a separate rotary table system with a modular design. The vertical rotary table with a diameter of 2250mm is easy to install and maintain and can quickly help customers upgrade their equipment. It can be matched with ordinary single-color injection molding machines to increase the application range. With the unique positioning structure of the rotary table, it can realize multi-station control of the rotary table and expansion of equipment functions. A multi-angle injection unit can recognize the injection molding from a single product to a multi-component product. This technology has been applied to tederic Dream T series.

Benefits of SpinSure™-V Independent Vertical Rotary Table

Applications of SpinSure™-V Independent Vertical Rotary Table

Tederic can develop a complete set of production solutions for customers: Improve production efficiency more humanely with the automatic material removal function.

Language