2021.06.03-04

June 3rd to 4th, The 16th Auto Lamp Industry Development Technical Form and the 7th Shanghai International Auto Lamp Exhibition (ALE) held in Shanghai Automobile Exhibition Center. The exhibition brought together well-known industry companies and experts to discuss the cutting-edge trends and technological innovations in auto lamps around the four major themes of "innovation, intelligence, connectivity, and perception art."

.webp)

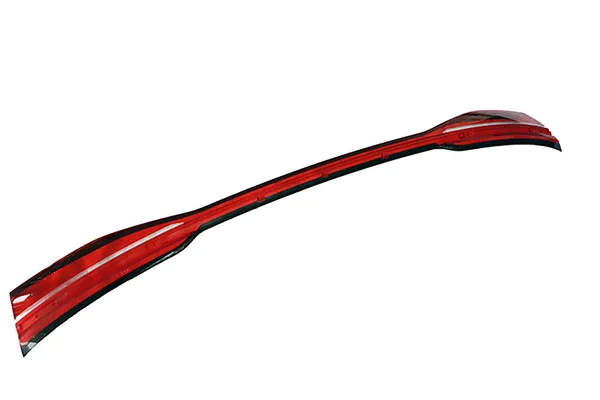

The car ambient light displayed by Tederic on-site attracted the attention of many insiders.

As a world-renowned manufacturer and solution provider of injection molding machines, Tederic has been committed to meeting the diverse needs of various auto parts manufacturers through excellent products, advanced technology, and rich industry experience to maintain high-cost performance and high competitiveness. At this exhibition, Tederic also demonstrated four major technologies and their highlights applicable for the automotive field:

Addshot-E ® independent electric auxiliary unit is a functional product designed based on all-electric precision molding technology. It can be matched with different injection molding machines and can realize the upgrade from single-color to multi-color injection molding without changing the original equipment structure.

High adaptability: It can be matched with any horizontal injection molding machine;

Independent control: It has a built-in controller and can complete switchover quickly in two hours, without changing the original equipment structure;

High-precision injection volume: The repeatability of injection weight can reach 1‰.

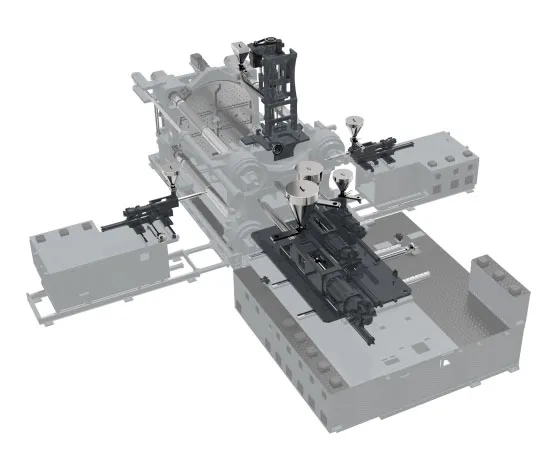

The same plastic product has different functional requirements in other parts. To achieve this production requirement on an injection molding machine, the MultiMold™ multi-color master technology is required. It can meet the possibility of multiple colors on one device through numerous injection units or multi-angle injection.

Multi-combination: Several independently controlled modular injection unit structures can be flexibly assembled in more than 30 ways;

Flexible: Four injection angles of MultiMold®-HL (horizontal lateral), MultiMold®-HP (flat parallel), MultiMold®-P (post), MultiMold®-V (vertical) can be freely arranged.

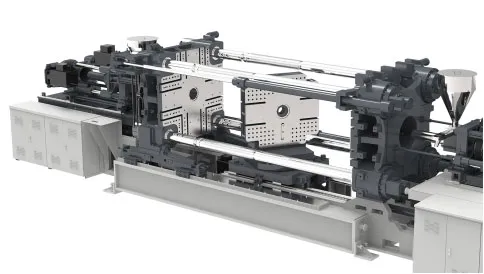

The traditional injection molding machine has a limited mold rotation space and cannot withstand over-weighted molds. The SpinSure®-H horizontal rotary table technology combines the middle-platen horizontal rotation function and the modular injection unit between frameworks of clamping units of two-platen injection molding machines, thus providing sufficient rotation space for the rotary table and allowing the mold to rotate beyond the space between tie bars.

High load-bearing capacity: The horizontal rotary table support structure can bear up to 50 tons of mold weight;

Suitable for large molds: It allows the mold to rotate beyond the space between tie bars, breaking through the limitation of traditional injection molding machines to molds;

Personalized customization: It can be customized according to actual production needs.

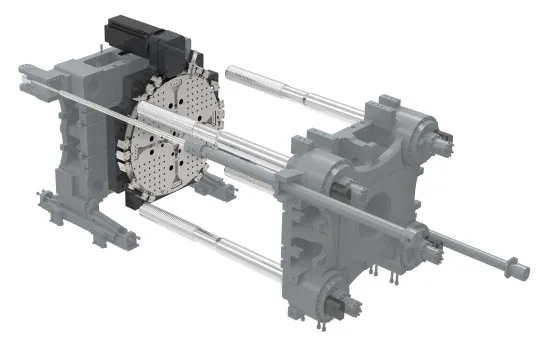

SpinSure®-V independent turntable technology

SpinSure®-V independent rotary table adopts a modular design for multi-color injection on a small injection molding machine. It can be freely matched with ordinary single-color injection molding machines and multi-angle injection units to realize injection molding from single to multi-component.

Personalized customization: It can be customized according to actual production needs;

Flexible: The modular design of an independent rotary table system is easy to install and maintain;

Durable: The high wear-resistant rotary table plane and internal lubrication system increase the service life of rotary tables.

Language