In addition, when the global decarbonization trend is clear, how to achieve efficient energy-saving and emission-reduction products in the automotive industry is also a concern.

Innovation is constantly changing people's understanding and cognition of headlights. As the world's leading provider of new EV lamp injection molding solutions, Tederic provides the world's first lamp supplier with a number of the most advanced NEO·E series electric IMM and automation solutions, driven by technological innovation, and continues to create value for more users around the world.

01Tederic: The best choice under the technology iteration

The high-end equipment manufacturing industry with high technology content and high added value is the core part of the entire manufacturing value chain.

In recent years, Chinese manufacturing equipment brands have continuously increased technology research and development efforts. The exploration and breakthrough speed of high-end manufacturing has accelerated like a snowball, and the technical level has gradually been leveled with European equipment.

In the context of technology iteration, customers actively explore Chinese high-end injection molding equipment. Coupled with "carbon neutral" production requirements, customers require suppliers to provide green, low-carbon products and services.

As a one-stop intelligent injection molding solution provider, the innovative solutions of high efficiency, high precision, and cleaner headlights brought by Tederic electric IMM will naturally become the best choice for customers.

02High-precision equipment enables enterprises to develop with high quality.

In the customer's production base, several Tederic electric injection molding machines NEO·E208c with TLRE12-1400 linear manipulators are neatly arranged.

Compared with ordinary optical parts, the lamp products belong to precision optical components, and the surface and size requirements are fine. At the same time, the particularity of the light transmission of the headlights leads to strict requirements for cleanliness and thermal stability, and the injection molding equipment needs to have high precision and stability.

In the face of the extremely high-quality requirements of products, Tederic has withstood the test of customers.

Tederic NEO·E electric Imm adopts full servo motor precision control, and repeated positioning accuracy of mold opening position up to 0.01mm.

Mode-locked structure motion curve optimization and injection double track design, injection stability, pressure control accuracy up to ±1 bar, can achieve 0.1% product quality repetition accuracy, effectively avoiding the flow mark and stress inequality defects of lamp optical parts.

03Leading the "carbon neutral" track Tederic solutions improve quality and efficiency

In recent years, China, the European Union, and many other countries and regions around the world have promoted carbon neutrality, and carbon neutrality has been extended to the whole life cycle of a car. As a leading supplier in the field of automotive electronics and lighting, customers also have a very clear demand for sustainable green production. In this regard, Tederic always insists on leading the "carbon neutral" track with technological innovation and gives an energy-saving solution that satisfies customers.

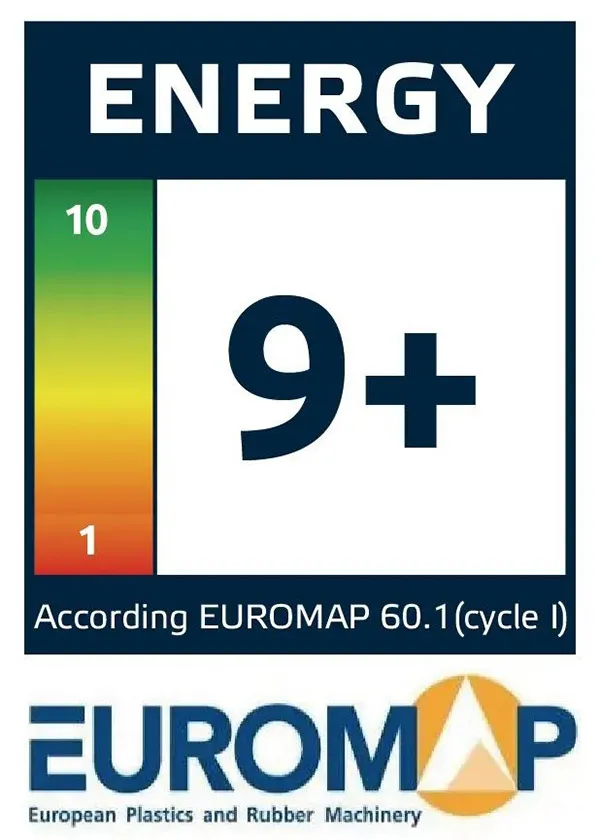

Tederic NEO·E electric IMM is equipped with an advanced energy recovery system as standard. According to Euromap60.1 energy consumption standard, Tederic NEO·E series products are more than 9+. Driven by technological updates, many products of the Tederic NEO·E II series can reach a higher energy saving level of Euromap 10+, which can save 15% compared with other motors.

While ensuring the high-precision production of lights, the ultra-high response of the new generation of the servo power system can also run continuously for more than 10min at full pressure and full speed, effectively shortening the production cycle.

In general, under the premise of the same control accuracy, the total energy consumption of Tederic NEO·E electric IMM can be saved by 60%-80%, helping customers to maximize the reduction of production costs. In addition, the number of equipment parts is small, troubleshooting is simple, and the maintenance cost of the equipment is further reduced.

As an enterprise with a complete industrial chain, Tederic has always taken it as its responsibility to create real value for customers. Use innovative technology to increase low-carbon manufacturing, and continue to integrate "Smart Green" into the production process of parts production, component assembly, and the whole machine assembly industry chain.

In the future, Tederic hopes to reach a partnership with more enterprises to work together to accelerate the release of EV industry capacity and help build a new model of "green travel" low-carbon life.