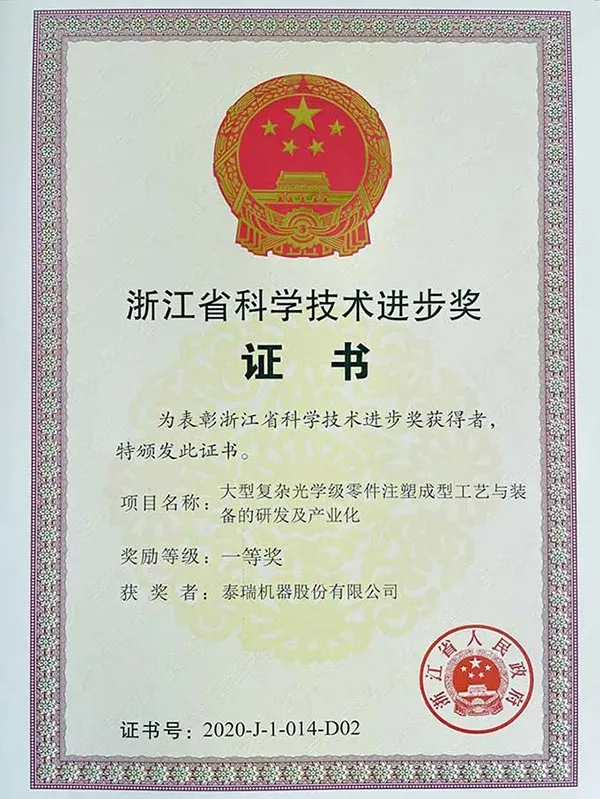

On June 15, Zhejiang Province Science and Technology Award Conference was held in Hangzhou. The 2020 Zhejiang Science and Technology Award, Natural Science Award, Technological Invention Award, Science and Technology Progress Award, and International Science and Technology Cooperation Award were awarded at the conference site to commend outstanding contributors in the province's science and technology field. The R&D project of Tederic Machinery Co., Ltd. "R&D project of injection molding process and equipment for large Complex Optical Grade Parts," won the first Science and Technology Progress Award of Zhejiang Province.

As a heavy-weight event in science, several awards presented at the conference represent the highest honor in science and technology in Zhejiang Province. They are a full display of the province's significant landmark achievements in scientific and technological innovation and a symbol of the "weathervane" of cutting-edge technology. In this project, the large-scale and complex optical-grade parts molding equipment developed by Tederic has conducted joint research on critical technologies such as independent precision control of large-scale injection molding equipment, large-scale optical-grade parts molding technology, and complete sets of equipment, and achieved a series of significant results.

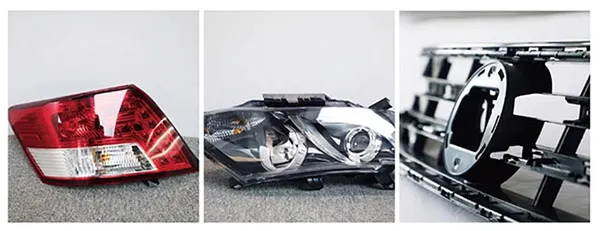

With the general trend of the lightweight automotive industry and consumers' demand for aesthetics and fashion of parts, traditional optical elements are also accelerating "plasticization." However, compared with ordinary plastic products, optical-grade plastic parts have essential differences in raw materials and molding processes, tricky to mold, and require high precision.

Application of optical grade plastic parts in the automotive field

Tederic has adopted three major technical highlights: "High-precision dual-loop control method for injection molding systems," "Multi-directional synergistic multi-layer integral injection and secondary mold closing process," "Horizontal heavy-duty turntable opposed molding and dynamic balancing technology for mold plates. " Overcome difficulties, make breakthroughs in innovation, and have significant advantages in dimensional accuracy, molding cycle, and optical characteristics. In addition, Tederic's Material solutions and high-end multi-component injection molding machines can provide auto parts, customers with overall solutions, and automated production solutions and continue to promote the development of the plastic molding equipment industry in the direction of high-end intelligence.

At present, the results of the project have been fully industrialized. In the field of auto parts are mainly used in optical-grade plastic parts represented by automobile lights, atmosphere lights, panoramic sunroofs, and display screens. In addition, the project is widely used by global auto parts leaders such as Röchling in Germany, and the products cover a large number of well-known car companies such as BYD, Audi, Volkswagen, and Ford.

Car atmosphere light

"Resolve a batch of "stuck neck" problems as soon as possible, carry out seed source "stuck neck" technical research, and aspire to fight a turnaround in the seed industry." Last year, General Secretary Xi Jinping once again mentioned the "neck sticking" problem that shackles scientific and technological innovation development at the Central Economic Conference.

For high-end large precision manufacturing field, for a long time, due to high-end equipment and the lack of key core technologies, our country's urgently needed such equipment has been heavily dependent on imports, appropriate equipment has been included in the national "Major Technical Equipment Independent Innovation Guide Directory."

Through critical technologies, the project results have filled the gaps in the injection molding process and equipment of large and complex optical-grade parts in China and also marked that the problem of foreign "stuck necks" in the field of high-end precision optical-grade parts has been solved, and it can completely replace imports. The first domestic 2000-ton multi-station injection molding machine developed by Tederic, after more than ten years of painstaking research and development, the leading indicators have been tested by industry authoritative testing agencies to be superior to foreign countries, completely breaking the foreign monopoly, it was appraised by the appraisal committee headed by two academicians that "the overall technology has reached the advanced international level." In addition, advanced international "Outstanding Product of Machinery Industry in the 40th Anniversary of Reform and Opening Up".

"Innovation is the first driving force to lead development. " For 18 years of deep cultivation in the field of injection molding machines, Tederic always insists on putting the spirit of "continuous innovation" into practice, relying on the model of"Mainly independent research and development, independent design, Complemented by industry-academia-research cooperation with higher education institutions and research units," promotes the development and reform of the industry. The winning of this award also demonstrates Tederic's significant advantages in independent research and development strength and technological innovation level. Taking this as an opportunity, based on the present and looking at the long-term, Tederic will unswervingly follow the road of "independent innovation" and contribute its strength to the high-end and high-quality development of domestic injection molding machines.

Language