This 2023CHINAPLAS, Tederic will provide a demonstration of CoinSure™ Injection Compression Molding Process, which is an efficient and precise program specifically for the field of new energy vehicles, focusing on "Empowered by innovation" to meet the requirements of high-quality production of optical parts and effectively improve the quality of automotive interior injection molding parts.

The program has been in Germany before the K-show, triggering a warm response from overseas customers. During 2023CHINAPLAS, CoinSure™ Injection Compression Molding Process made a new appearance in the Chinese market after optimizing and upgrading.

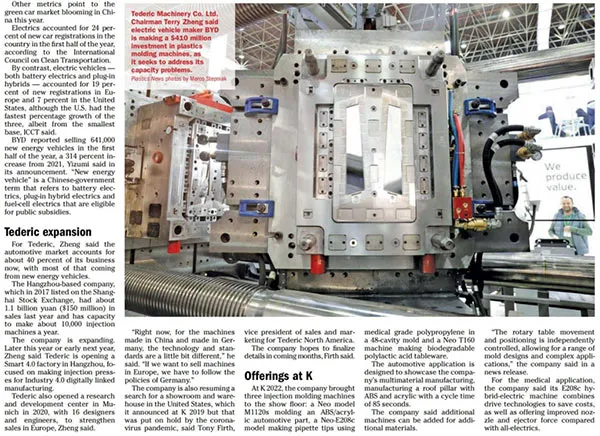

▲ An exclusive interview with Tederic by overseas media Plastics News

CoinSure™ Injection Compression Molding Process promotes the optical properties of products so that plastic products can meet the quality requirements of optical parts. Integrated molding, to ensure the perfect dimensional accuracy of products at the same time, reduce mold loss and injection molding machine energy consumption, and reduce customer costs. It is suitable for high-precision and high-quality product moldings, such as transparent parts of automobiles, car lights, lenses, and high-precision optical parts of national defense, aerospace, and deep sea exploration.

Highlights of the program:

1. Reduce the injection pressure, reduce the internal stress of optical products, improve the optical properties of products, meet the high-quality requirements of optical parts, and reduce the subsequent mold maintenance cost.

2. Four pull rod independent control, in the injection compression molding process, pull rod position control accuracy: static up to ±0.01mm, to ensure the perfect dimensional accuracy of products.

3. Integrated molding to meet special production needs such as complex surfaces and help new energy vehicle brands realize product design freedom.

As one of Tederic's core competitive products, the NEO·M1120s horizontal injection molding machine has excellent performance. Its turntable with brake servo drive and sufficient turning space can adapt to the customer's extensive process needs and has won the provincial scientific progress award many times, showing the technical reserve strength of Tederic in the auto parts field.

* Exhibition machine NEO·M was awarded "Outstanding Product of Mechanical Industry in the 40th Anniversary of Reform and Opening Up"

First prize in the Zhejiang Science and Technology Progress Award two times

With years of technical accumulation and competitive advantages in the field of multi-material injection molding, Tederic has become one of the few enterprises in the world with the ability of R&D and manufacturing of super-tonnage multi-component injection molding machines.

The NEO·Ms series has accumulated many years of injection molding equipment research and development and manufacturing experience of Tederic, currently covering 1120t-3520t. It is the first to realize the research and development of the injection molding machine replacing the largest number of imported stations at home.

At present, the NEO·Ms series has been widely used in various industries such as home appliances, auto parts, and logistics. Aiming at the automobile industry, we have provided injection molding solutions for the high-quality production of many headlight optical parts such as highlighter external columns, headlamps, headlamp shades, and tail lamp shades for many domestic auto parts manufacturing enterprises.

Tederic NEO·Ms series has great advantages in the production of large two-color and three-color plastic products, as well as the processing of two paired products as a monochrome machine.

▲ Project partner and booth number

Tederic looks forward to your visit

Booth No. : 12C41

Welcome to Tederic CHINAPLAS Booth 12C41

Or visit www.tedericglobal.com to learn more!