Products

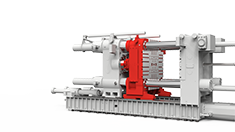

Three-Platen Direct Pressure Structure

Uniform distribution of clamping force, reduce flash and ensure casting accuracy.

Arbitrary setting of opening and closing die stroke according to product size and high production efficiency.

With the function of self-adjusting mode-locking force, the mode-locking force is consistent.

Compact structure, short pipeline cycle time, improve site utilization.

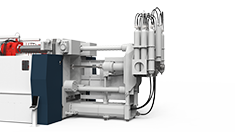

10000HZ high performance controller

It is equipped with a high-performance controller with a scanning frequency of 10000HZ. To ensure the stability of injection, it uses the original SNP real-time control system (fifth-order PID algorithm + MCK large model self-learning algorithm).

International injection system

The introduction of German advanced injection technology, the use of non-pulsating oil circuits, exclusive custom servo valves, and energy storage systems.

With a lightweight injection load design, 40% higher than the conventional dynamic injection force, the casting molding effect is better.

SmartCast casting process system

Adopts European foundry process algorithm to automatically calculate process parameters and shorten commissioning time.

Real-time monitoring of the die casting process improves product yield and ensures casting quality.

Functions such as OEE, CMK, energy consumption, and output statistics are configured to facilitate production management and device management.

Language