This exhibition brings together more than 2,100 exhibitors, with a display scale of 240,000 square meters, and exhibitors from nearly 100 countries and regions worldwide, showing the real strength and level of world-class machinery and equipment manufacturing development.

The NEO·H500b Rotary mold core injection molding machine and NEO·E200II electric injection molding machine, the innovative products of Tederic in the field of car lamp injection molding, were unveiled at booth C15 in Hall 10. On-site interpretation of high-precision intelligent injection molding solutions in car light optical parts, a full range of Tederic manufacturing, and international brand products favored by domestic and foreign customers.

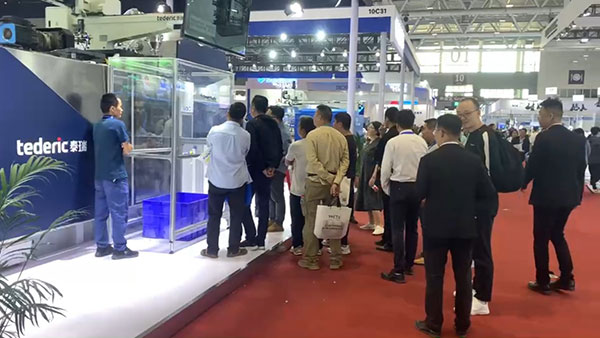

At the scene, Tederic conducted in-depth exchanges with buyers from around the world, provided detailed product introductions and answers for customers, and jointly discussed the cutting-edge technology and product technology innovation of optical components in the field of automotive headlights.

The two major technical application solutions break the international "technical barriers," solve several "jam neck" key technical problems, and enable the lamp industry to achieve green, low-carbon, high-quality development.

01. OptiSure™ multi-layer thick wall lens injection molding solution

As an important part of the car safety module, the car lamp is related to driving safety, and it is also one of the most difficult and demanding parts in the car's plastic parts.

The Tederic OptiSure™ multi-layer thick wall lens injection molding solution attracted customers' attention at the booth. As a representative solution to break the international technology monopoly, the solution solves the problem that ordinary single-layer injection molding processing can not be efficient and precise production, using layered injection molding and external cooling to ensure high-quality production of optical lenses and improve production efficiency by 30%.

▲ NEO·H500b rotary mold core injection molding machine

▲ Multi-layer thick wall lens

- With OptiSure multi-layer injection molding technology, using layered injection molding and external cooling, product production efficiency is increased by 30%.

- Flexible multi-stage injection molding technology, the same shooting table can carry out multiple injection and storage actions of different processes within the production cycle, solving the problem of yellowing caused by excessive retention time of raw materials in the barrel and creating greater design freedom for mold developers.

- An electric beam controls the injection speed fluctuation within 0.2mm/s, effectively avoiding the flow marks and stress inequality defects of thick-walled optical parts.

- With electro-hydraulic composite technology, the product's energy consumption is less than 0.32 kWh/kg and contains a higher "green" content.

02. Automotive thick-wall lens injection molding solution

With the accelerated pace of global decarbonization transformation, the new energy vehicle industry chain may have greater structural changes. On the other side of the booth, the high-precision, low-energy thick wall lens demonstration scheme brought by Tederic's electric injection molding machine is also eye-catching.

The scheme has an advanced energy recovery system; the injection weight repetition accuracy is less than 0.1%, and it is green, efficient, and flexible. It can promote the transformation and upgrading of users and effectively help the deep decarbonization of society.

▲ NEO·E200II electric injection molding machine

▲ Light optical lens

- Equipped with an advanced energy recovery system, the energy consumption level is in line with Euromap9+, compared with servo hydraulic press to save more than 35%, reduce production costs, and reduce carbon emissions.

- Full servo motor precision control, dry cycle up to 1.5s, injection speed up to 400mm/s, enabling efficiency and quality for the automotive industry.

- No oil temperature internal leakage and other common hydraulic interference, equipment parameters are stable all year round; Small number of parts, easy troubleshooting, reduced maintenance costs.

Green transformation, energy saving, and carbon reduction can not be separated from the vanguard power of enterprises. In the new energy lamp optical parts manufacturing equipment, Tederic has enough competitiveness to compete with German and Japanese high-end manufacturers.

In the future, relying on stable and reliable products, innovative leading technology, green environmental protection concepts, and perfect after-sales service, Tederic will take root in China and look to the world. I also hope to bring my design concept and craftsman spirit into the world machinery market and inject new momentum into the global injection molding development!